From seed sowing to flowering, harvesting, sifting and winding cigars, there are many stages to the production of a cigar for us to enjoy… So, “smokers”, please don’t forget. Here are 10 things to do before you decide to cut, light and enjoy your favorite cigar.

In the world of high-end cigars, we sometimes get bogged down in an endless world of different choices, recommendations, and personal opinions. Those are complicated and confusing preferences even for longtime hobbyists. To help you make your own decisions and choices, we’ve put together information to provide insight and perspective for every cigar lover, from novices to novices. cigars, novices, seasoned smokers or professional cigar aficionados.

The things shared below are not mandatory standards when thưởng thức xì gà, but rather the most basic knowledge to explain and highlight some aspects of the premium cigar industry. They also include a few helpful tips to make the experience and enjoyment of cigars more enjoyable.

1. Cigars are an all-natural and handcrafted product

Commonly mentioned keywords such as “Natural” or “Artisan” are used a lot in an abusive way in many cigar products around the world today, but for high-quality cigars. Classy and expensive they totally deserve these words. They are made of one thing, and only one thing is tobacco leaves. Completely pure and without any mixing or use of artificial flavors. Everything from the flavor to the color of the cigars is achieved through natural methods – and that is part of the inherent beauty of cigars.

In fact, there are only a few products on the market that are made entirely naturally, specifically here cigars. The perceived flavors, whether sweet or spicy, are created completely naturally. Even the different brown color of tobacco leaves is created through a natural organic process, without the intervention of aging chemicals or dyes, and of course without preservatives. , no external sweeteners either natural or chemical. Additives or chemicals are categories that belong to tobacco products or industrially rolled cigar products, which are mass-produced in billions of cigarettes.

Rolling the perfect cigar is a manual skill that takes years of practice to master and achieve. Mixing tobacco leaves is also an artistic skill and it has the same formulas as a science. Blenders often have to be creative because tobacco is a product of agriculture, it depends on the change of weather, so Blenders must be very observant and have the skills to handle those variables.

Similar to wine, some wines will taste better than others if the weather conditions are right for that grape season. But with cigars, Blender will have to try to give the best flavor to ensure their products have the same quality through the changes of weather in different years. Of course, they are not 100% correct, which is also why we sometimes see different cigarettes smoked in different years. It’s like any other craft, you won’t find two cigars that are 100% the same. The best cigars are the perfect combination of two factors: a professional producer and a piece of land with the best natural conditions.

2. Up to 200 hands have ever touched the cigar you own

It is said that more than 200 hands have touched the cigar in your possession, with many claiming that number is even higher. So, every time you light a cigar, remember that many, many people with different skills have contributed to creating the handmade cigar you are smoking.

It starts with the selection of seeds and cultivation in greenhouses. Tobacco plants start from small seeds, they are grown on trays in a greenhouse. When the seedlings are a few inches, they begin to be planted in suitable fields so that they can grow stronger. When the plants are fully mature, meeting the requirements for tobacco selection, they are harvested and hung in shacks to dry and turn brown. During that process, dozens of pairs of hands came into contact with these cigars until they left the farms.

The tobacco leaves are then selected, brought to the facility, stacked in preparation for fermentation. Once the fermentation is complete, the leaf piles are separated and placed on different shelves to return them to a dry and separated state. Next, they are filtered again, then bundled together to continue the aging process. After a few years of aging (depending on the medication required) they are old enough, they are repackaged. And now, they are placed in a room with standard humidity by special misting method and graded by color. This process is again the contact of many different hands.

As for the outer foil, it continues to undergo another process of stamping or laminating. This process is intended to completely remove the large veins. Usually these steps are done entirely by hand, sometimes done with some kind of vein stripper. For filler leaves (core leaves), workers will remove the main leaf veins by hand, leaving the rest intact. Thus, this process is the contact of many other hands.

Don’t forget the rolling process. This process is only performed by certain factory workers. They will arrange the appropriate tobacco for each person to roll. Next the Torcedors will take the appropriate tobacco to bring to their rolling table, they will begin to roll them according to the blender’s specified recipes, they will cut, roll and press the cigars with hand to shape. This blend is set in extremely precise proportions by the skillful and experienced hands of artisans who have achieved an exceptional smoking and rolling experience – a formula that defines many two more hands on your cigar.

Finished cigars, after being rolled, are selected and sorted by color in a consistent manner, then they are brought into the room to continue the required aging process. Finally, they are selected one more time and go through the process of stamping and boxing and sending.

Above are the basic steps in the production of a cigar. In fact, there are many different quality control steps in each production stage, and almost all of these steps are done by hand. But what’s more important is that a hand-rolled cigar is a massive human endeavor at every level of expertise.

3. Cigar leaves must undergo fermentation

Fermentation, common to wine and spirits producers, is defined as a process that converts sugars in organic matter to alcohol, usually with the use of yeast. In the tobacco industry, it is a microbial fermentation and decomposition of organic matter through the use of water, pressure and oxygen. No alcohol is produced during tobacco fermentation, but the process does release heat because it changes the chemical composition and physical properties of the leaves through moisture and oxidation.

Tobacco leaves undergo fermentation for one simple reason: to make the tobacco taste better. This process affects the taste and smell of tobacco, reducing acidity and bitterness while bringing out more of the grassy, nut, or grainy flavors and becoming sweeter.

The fermentation process is quite simple. Once the tobacco has been brought into the same room, the leaves are folded into large piles called pilónes. The only thing added is water. The weight of the pile creates pressure while enzymatic and bacterial decomposition generates heat. The piles are checked daily and the temperature is monitored. When the internal temperature of these pilónes reaches a certain point, the stack of cigarettes is removed, rotated by hand, and carefully folded.

Ideally, tobacco would be graded and stacked for fermentation according to leaf size and type. Different sized leaves and different types of tobacco are fermented at different rates. Therefore, the drug stacks should have the most similarity in leaf size and type. The meaning of this is to change the natural flavor of the tobacco from bitter, spicy to a more flavorful and sweet state. Tobacco after fermentation often has an acrid aftertaste and the smell of ammonia. This is not a process that can be skipped, cannot be rushed, and is absolutely essential in the production of premium cigars.

4. Aging is an important process

Aging is an extremely important process both before and after the cigar has been finished. The aging process is not only carried out before the tobacco leaves are rolled, the cigars immediately after being rolled, they are immediately transferred to a separate room for the next aging process. It is guaranteed access to extremely precise and standardized temperature and humidity conditions. They are also regularly monitored and controlled with utmost care.

Tobacco leaves are aged after fermentation, in the aging process, the tobacco leaves are re-packed into tight bales. Here, they will undergo a very slow, steady breakdown of the carotenoids, which gives important properties to the desired tobacco leaves. This leaf aging process also causes the tobacco leaves to become more ripe and shiny. Helps to remove natural tobacco content or chlorophyll nodules. If you’ve ever smoked a cigar that tastes like fresh grass or fresh green beans, then it’s definitely not mature enough. If the tobacco smoke has a lot of flavors of almonds, raisins and oranges, it has been sufficiently aged.

But there is another aging, which is aging done by the cigar consumers themselves. When canned cigars arrive in stores, a customer may wish to further age the cigars for a long time. Similar to wine aging, this aging process helps to dissipate all the remaining acid groups in the cigar and makes the cigars more beautiful, smoother and more polished.

Perfect aging is when the cigar you carry reaches the ultimate peak of flavor. At this peak, the flavors are not only balanced and blended, but undesirable qualities such as spiciness, bitterness, astringency, or roughness of the tobacco also dissipate. A really great cigarette even its aging can last for decades as long as the temperature and humidity conditions remain stable.

However, there are a few caveats: don’t over-age the cigar. Excessively prolonged aging can result in a cigar losing flavor and shape, causing the cigar to be isotopic and ultimately tasteless. In addition, if the aging process is incorrect, it can lead to the cigar becoming bitter, bitter and spoiled.

5. Understanding the Structure of a Cigar

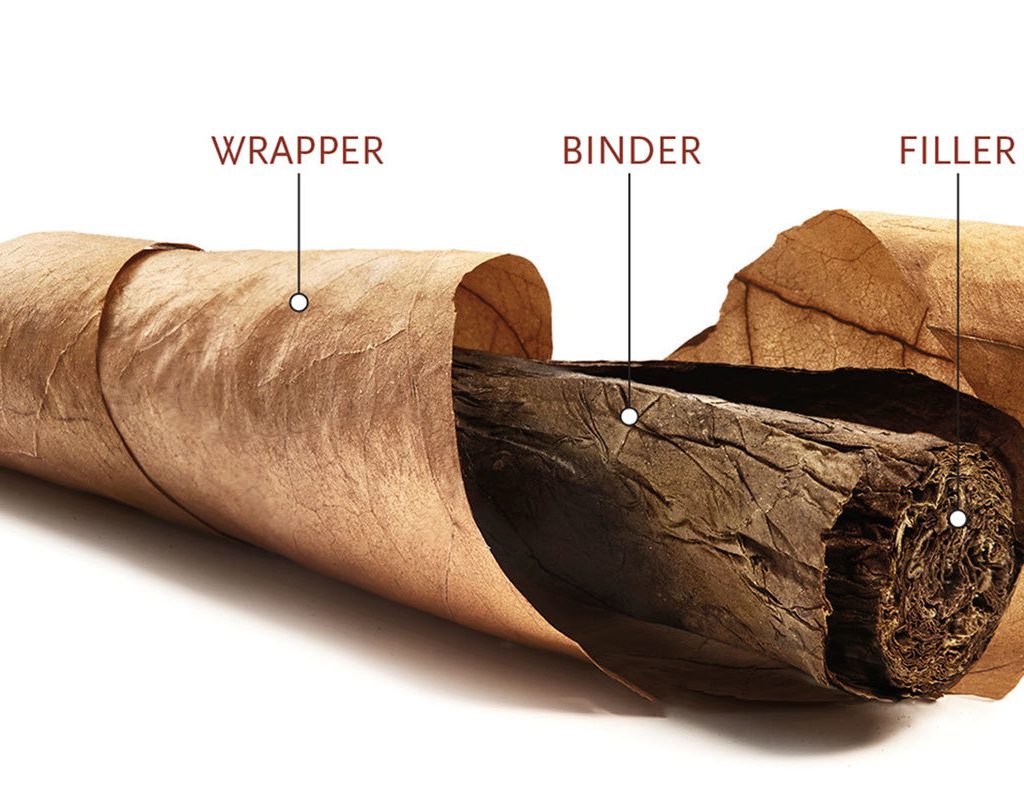

A cigar is made up of three main parts: the wrapper, the binder, and the filler. All three of these parts form a smoking system and combine into a unified whole that natural tobacco leaves are called cigars.

Wrapper leaf (outer leaf) is the leaf that wraps the entire finish around the outside of the cigar. This is also the most valuable leaf part, as these outer leaves need to retain their integrity as well as flavor. If the leaf is too sinewy (many thick veins) and rough or has any other blemishes, it is no longer classified as a wrapper.

Lá binder (lá gắn kết) là lá có nhiệm vụ liên kết và tạo ra ngoại hình cơ bản của điếu thuốc. The binder is usually the same type as the wrapper itself but does not require smoothness, because we cannot see them. The binder in a cigar is the layer of foil just below the wrapper, which holds the filter leaves in place, which is why it’s called the binder. The burning process of the binder is also very important, because a well-burned binder will help the filler core foil system to burn more evenly, especially in the case that the filler layer contains many complex types of leaves that are difficult to burn.

The filler leaf (core leaf) is where drug makers (blenders) can unleash their creativity. They can use leaves from different countries, different regions or different locations on the same medicinal plant, etc. to create the flavor and strength they desire. Like wrappers and binders, filler leaves are also very long-life tobaccos, designed for slow burning, but they offer a more aromatic and delicious taste experience.

The base of the cigarette – where the light is lit – is where you can clearly see the core of the cigarette. The tip of the cigarette is where the cigarette ends, they are usually completed by a cap, which helps to keep the wrapper from falling off. The endings of a cigarette always require very high skill of the cigar maker.

A good texture is key and there is never a limit. An improperly made cigar will not draw smoke and is difficult to burn, which will drastically affect the taste and enjoyment, no matter how well the raw materials are handled.

(to be continued…)